I done a quick boost leak check on the car today and I found a couple of leaks

The one I had a feeling was gonna be there was around where the turbo compressor housing bolts to the core as shown here

I had a 90 bend welded to the comp housing after the engine dyno so this is a new issue, it's warped the housing and when I re fitted it I had to rub it down a bit to get it to seat properly so I knew the chances were it was gonna be an issue,

I may be able to get this re faced in a lathe to sort this but time will tell,

The second spot was from around the TPS where it seats on the theottle body shown here

I can't see there is anything that can be done about this 1 though? This has not been changed so this would of been present during mapping on the engine dyno

Any 1 else had this issue or will the tps 1 be minor and not really an issue?

I pressurised the system to 2 bar and it drops straight away!

Thanks

Marc

The one I had a feeling was gonna be there was around where the turbo compressor housing bolts to the core as shown here

I had a 90 bend welded to the comp housing after the engine dyno so this is a new issue, it's warped the housing and when I re fitted it I had to rub it down a bit to get it to seat properly so I knew the chances were it was gonna be an issue,

I may be able to get this re faced in a lathe to sort this but time will tell,

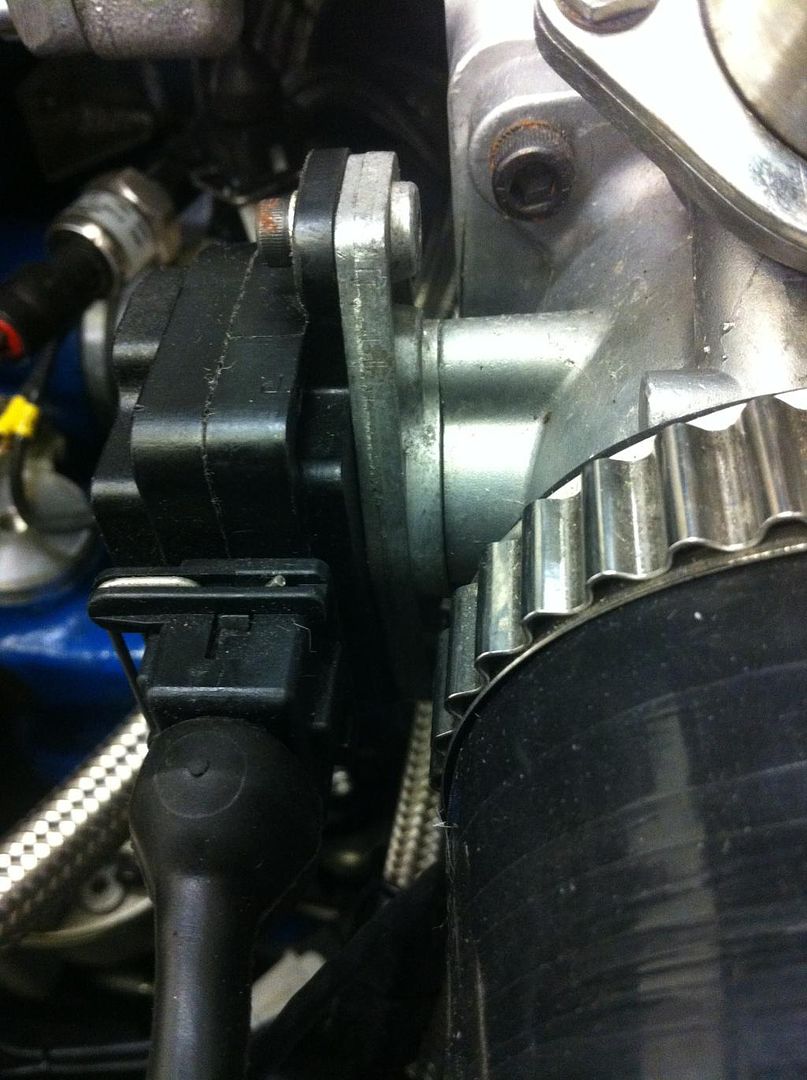

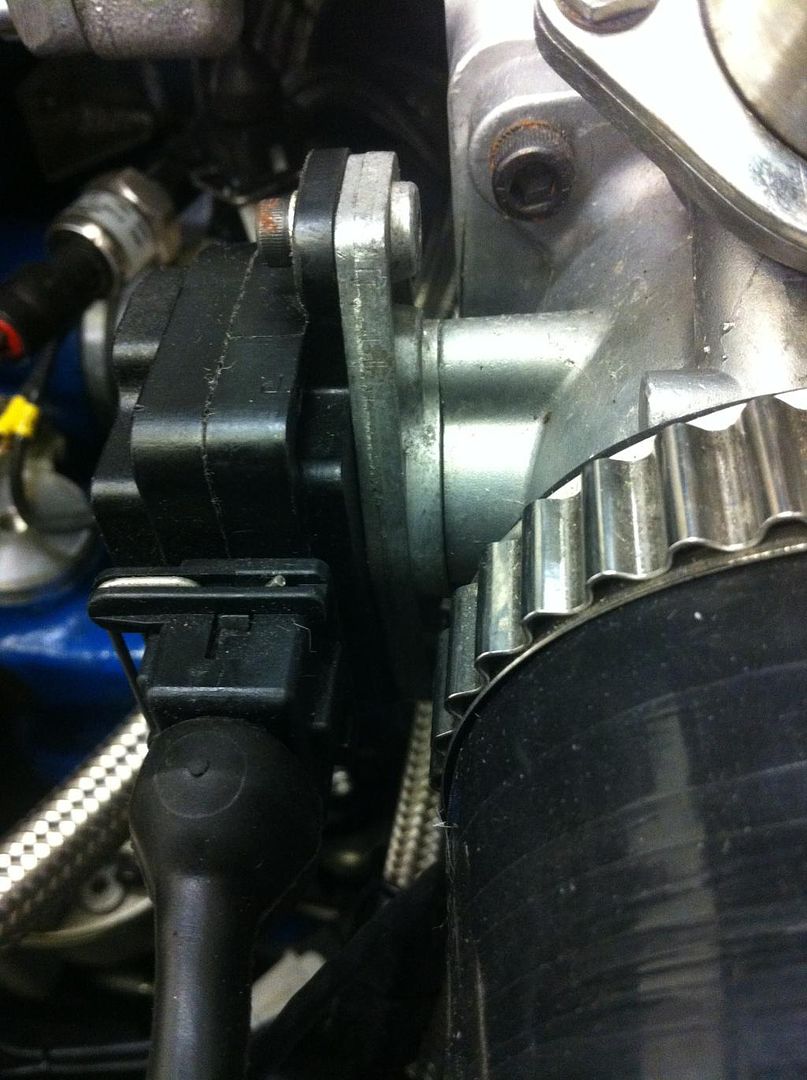

The second spot was from around the TPS where it seats on the theottle body shown here

I can't see there is anything that can be done about this 1 though? This has not been changed so this would of been present during mapping on the engine dyno

Any 1 else had this issue or will the tps 1 be minor and not really an issue?

I pressurised the system to 2 bar and it drops straight away!

Thanks

Marc

.....Leak on turbo comp housing you can rectify with putting silicon on o ring..did mine like that..

.....Leak on turbo comp housing you can rectify with putting silicon on o ring..did mine like that..

Can you hear it.

Can you hear it.

Comment